Global Compliance, Proven Reliability: Our Polymer Seals and Profile Solutions

Designed to meet the most demanding market requirements, delivering superior performance and longevity across four core sectors. Our design and manufacturing processes are based not only on regional expectations but also on full compliance with the world's strictest international regulatory frameworks. By leveraging our advanced R&D and production capabilities, we process EPDM, TPE, TPV, and Silicone materials across our specialized facilities to deliver the most efficient, custom-tailored solutions that align perfectly with our customers' unique requirements.

Core Industries

Construction

Industrial Doors & Gates

Solar Energy

Infrastructure

Marine Sector

Industrial Applications

Construction

Construction Materials, Window, Door and Facade Systems, Industrial doors and Gates.

Our products comply with key standards to ensure the energy efficiency, sealing, and mechanical strength of buildings:

Industrial Doors & Gates

Global Standards, Intelligent Door Engineering

AluVentura serves the global market with high-performance sealing solutions tailored to specific door types. Beyond insulation, we integrate advanced safety and automation technologies into our profiles:

1. Industrial Doors, Sectional Doors & Loading Bays

Compliance: Full compliance with EN 13241 (Product Safety) and EN 12427 (Air Permeability).

Durability: ASTM D2000 classified EPDM and TPV compounds ensure resilience from -50°C to +150°C.

2. Hangar Gates & Heavy-Duty Systems

Wind & Weather: Certified to EN 12424 for high wind load resistance and ASTM D1149 for superior ozone resistance.

Protection: Optional fire-retardant seals (UL 94) and ingress protection up to IP67 / IP68.

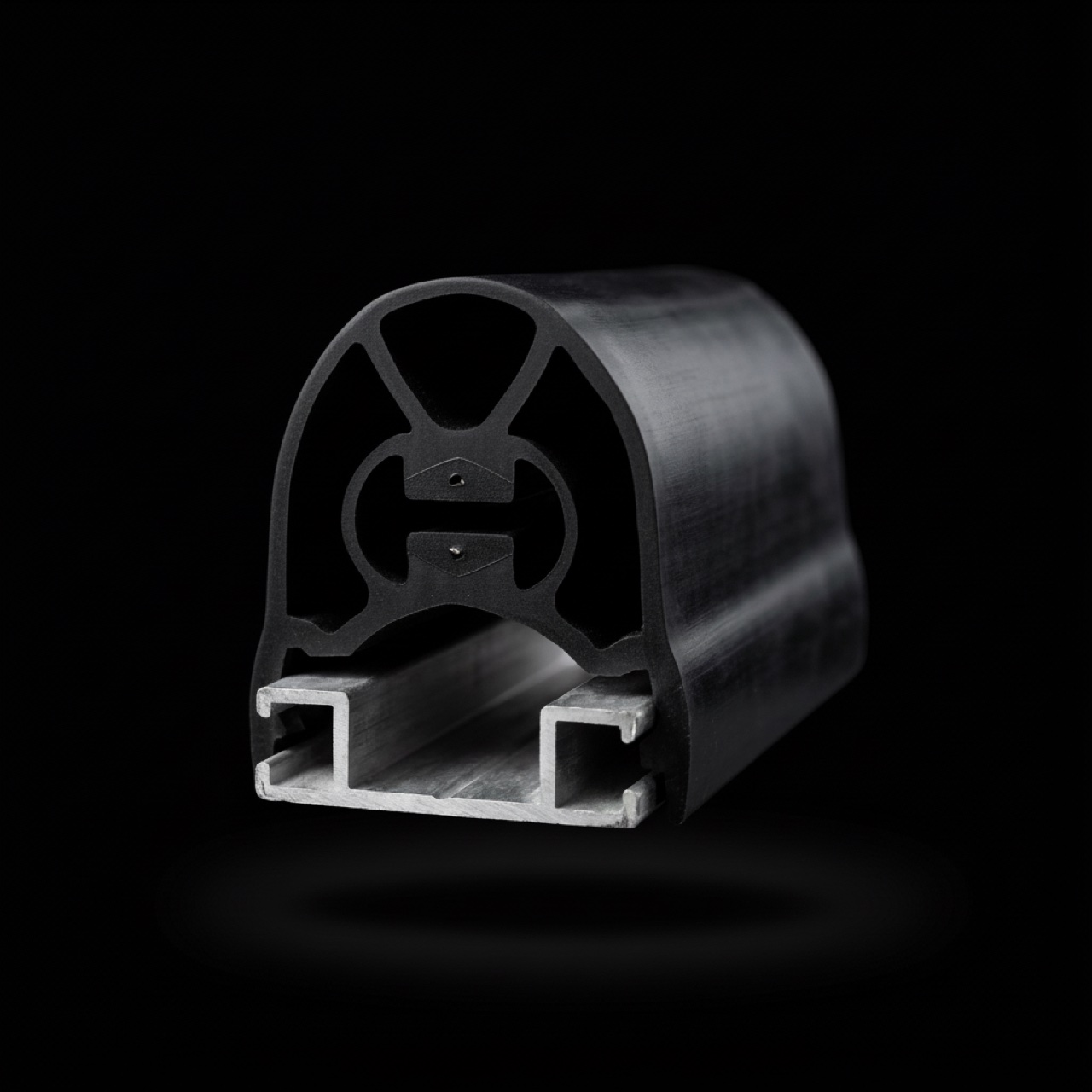

3. Garage Doors & Roller Shutters (Smart Safety Integration)

High-precision profiles designed for security and automated operation.

Sensor Compatibility: Our seals are specifically engineered to be compatible with optical sensors, ensuring seamless integration with modern safety edge systems.

Integrated Circuits: Upon request, we manufacture profiles with integrated copper wiring. This conductive technology allows the seal to act as a trigger for electrical circuits, enabling real-time mechanism control and obstruction detection to prevent accidents.

Precision & Safety: Aligned with EN 12453 and ANSI/DASMA 102, providing a perfect balance between mechanical flexibility and electronic responsiveness.

4. Controlled Atmosphere & Ripening Room Doors

Gas-Tight Integrity: Specialized profiles meeting EN 1561 / 1562 for hermetic sealing, essential for ethylene and CO2 management.

Thermal Control: Aligned with ASHRAE standards to prevent thermal bridges.

Global Market Compliance

AluVentura products meet BS EN 12600 (UK), ANSI/DASMA (USA), and AS/NZS (Australia) regional specifications.

AluVentura: Combining advanced material science with intelligent automation for the next generation of door systems.

Solar Energy

Energy Durability: Solar Energy (PV) Systems

Our seals and profiles are tested against extreme environmental stresses to ensure the long-term safety and performance of PV modules:

Infrastructure

Sealing Assurance: Infrastructure Systems, Tunnels, Highways

We guarantee the material quality required to maintain the sealing integrity of underground and fluid conveyance systems:

Concrete pipe gaskets

Tunnel Segment profiles

Highway expansion profile

Marine Sector

Extreme Condition Resistance: Marine Sector

Our seals and profiles comply with the stringent requirements of shipbuilding and offshore applications. Our primary focus in this area is fire safety and low smoke/toxicity requirements (under SOLAS) as mandated by the International Maritime Organization (IMO). Furthermore, the reliability of our products is verified through certification processes by leading classification societies such as DNV (Det Norske Veritas), Lloyd's Register, or ABS. Material durability emphasizes superior performance against intense salt water, vibration, and chemicals.

Material Qualification and Dimensional Precision

To ensure consistency across all these sectors, we validate the physical and aging properties of our polymer materials through international testing:

Standards such as UL 94 (fire safety); ASTM G154 / G155 (accelerated weathering for UV and climate resistance); ISO 188 (heat aging); mechanical property tests ASTM D412 (tensile strength) and ASTM D2240 (hardness); and ISO 3302 (dimensional tolerances) guarantee the precision of our products and form the foundation of our manufacturing.

The quality of our products is highlighted not only by compliance with international standards but also by their proven, long-lasting performance that often exceeds these test requirements.